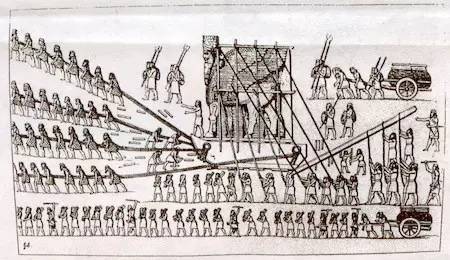

When it comes to the origin of bearings, it goes back to ancient Egypt. In the early form of linear motion bearing, a row of wooden bars were placed under the skid. This technique may be traced back to the construction of the Great Pyramid of Giza, although there is no clear evidence. Modern linear motion bearings use a working principle, but sometimes balls are used instead of rollers.

Initial stage

From heavy-duty wheel shaft and machine tool spindle to precise clock parts, rotating bearings are needed in many occasions. The simplest rotating bearing is the sleeve bearing, which is just a sleeve sandwiched between the wheel and axle. This design is then replaced by rolling bearings, which use a lot of cylindrical rollers instead of the original bushes. Each roller is like a separate wheel. The earliest practical rolling bearing with a cage was invented by watchmaker John Harrison in 1760 for the H3 chronometer.

In the 17th century, Galileo made the first description of the ball bearing of "fixed ball", or "cage ball". But for quite a long time, the installation of bearings on the machine has not been realized. The first patent on the ball raceway was in 1794. Philip Vaughn, an iron maker in camassan, Wales, used the ball bearing as the axle bearing of a four-wheel carriage. From then on until the 1950s and 1960s, the ball bearing was widely used in children's carousels, propeller shafts, gun turrets, armchairs and bicycles On the axis,

In 1883, Friedrich Fisher, founder of FAG, put forward the idea of grinding steel balls of the same size and accurate roundness with suitable production machines. This laid the foundation for the creation of an independent bearing industry.

Growth period

The second world wars stimulated the development of military industry. The status of bearing military industry is increasingly significant. In addition, the rapid development of science and technology, the short-term stability of the first World War and the urgent need for arms in the second world war prompted the rapid growth of world bearing industry and the increase of bearing varieties, which are widely used in automobiles, airplanes, tanks and armored vehicles, machine tools, instruments, meters, bicycles, sewing machines, etc Areas.

During the Second World War, with the modernization of the means of war, people's understanding and attention to bearings sublimated to an unprecedented level. All countries are in urgent need of bearings and eager to establish bearing industry. As a result, a large number of bearing factories have appeared in various countries. It can be seen from the selection of points when the Allied forces attacked the Nazi Germany. Large scale cluster bombing, which destroyed the morale and economy of the enemy at one stroke, was a typical tactic of the Second World War. When they arrived in Germany to attack their targets, the Allies believed that in order to weaken the enemy's combat effectiveness, they must focus on bombing German submarine manufacturers and bases, aircraft manufacturers, bearing factories, oil refineries, synthetic rubber factories and vehicles. The bearing factory was set as the key bombing target. The small town of Schweinfurt, which was concentrated by the German bearing factory, was bombed twice in August and October 1943. It was the US ace air force eight that carried out the bombing mission. Albert schumper, the Minister of military supplies of Nazi Germany, admitted that the bombing in August reduced German bearing production by 38%, while the bombing in October damaged 65% of bearing enterprises.

Development period

With the rapid development of aerospace, nuclear industry, electronic computer, photoelectric magnetic instrument, precision machinery and other high-tech, the world bearing industry, which embodies the level of modern science and technology, has entered a new era of comprehensive innovation and manufacturing technology, rapid development of varieties, vigorously improving performance and accuracy, and increasingly mature and perfect history.

In this period, there are all kinds of bearings with various purposes. At present, there are tens of thousands of types of bearings. The super large bearings are as large as 38 meters, and the micro bearings are as small as 0.0 mm. That is to say, there are traditional single row, double row, multi row ball bearings, roller bearings, needle roller bearings, tapered bearings, and even non lubricated bearings, self-lubricating bearings, angular contact bearings, conveyor bearings, universal joint bearings, super bearings Thin wall bearing, hub unit bearing, air bearing, linear bearing, superconducting bearing, etc.